XSG Series Spin Flash Dryer

Product Name:XSG Series Spin Flash Dryer

Details

Descriptions

XSG series roating drier is developed by our company, and its techinology is based on advance techinology adored.The machine is including many superiority, such as reasonable design, compact stuction, widly utilization, grrat productive capacity,good quality, high effect and save energy, Drying, grinding and sieve are completed in one equipment in once time. It eliminate pollution and the techinology is reached international advance level.

Principles

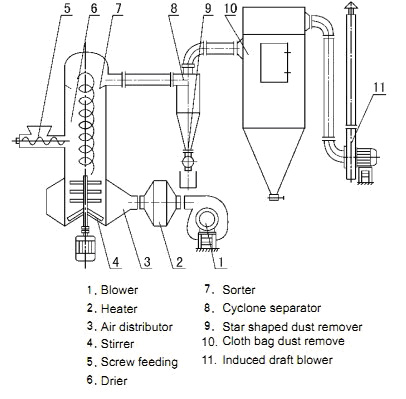

Hot air from machine bottom with suitable atomizing speed enter into the stirring and crushing room, it process raw material by cutting, shearing, blowing, floating and rotating. Then raw material is granulated through centrifugating, shearing, impacting and friction effect. This strengthens the process of heat exchange and water evaporation. Materials enters into the drier through the screwing feeding ostium, under the powerful high speed effect of stirring, materials are distributed by the function of striking, friction, shearing and cutting, raw materials are instantly smashed and fully contact with hot air, they are heated and dried, the dried powder material will be raised with the hot-air flow, small particles are discharged from the ring center and collected by cyclone segregator, the rest of materials are kept by graded ring and processed by centrifugal action, throw forward to the inside wall; then, drop to bottom, smashed and dried again. Because gas and solid are rotated together, inertia of solid is bigger than gas and the relative velocity between solid and gas is great, this strengthens the process of heating exchange. Therefore, this machine has strong drying capacity.

Features

◎The material is acted by centrifugal force, shearing force, impact and friction, the particle is very small and is in high degree distributing state. Meanwhile the relative speed between air and solid is big, it strengths mass and heat transmission. So it makes the machine has high output.

◎The hot air will enter into the bottom of the dryer and produce vigorous eddy airflow. It will produce strong washing out and bring out effect to material and eliminate the phenomenon of adhering wall.

◎At the area of high temperature at the bottom of dryer, thermal sensitive material does not contact with hot surface. It solves coking and discoloring problem of thermal sensitive material.

◎Because high cycle speed and short staying time of material in drying chamber, high efficiency and big production of small equipment can be got.

◎There is eddy piece in drying chamber. It can control moisture of material at lowest level.

◎The distributor at up part of drying chamber can control size and humidity of material at outlet.

Skech of Structure Technical parameters

Technical parameters

| Type | Barrel | Main machine dimensions | Treatment | Water evaporation | Floor space |

| diameter(mm) | (mm) | wind capacity (m3/h) | quantity(kg/h) | m2 | |

| XSG-4 | 400 | 4500 | 1350~2250 | 25~75 | 3×8 |

| XSG-6 | 600 | 5000 | 3050~5090 | 55~160 | 3.5×9 |

| XSG-8 | 800 | 6100 | 5400~9050 | 100~300 | 5×10 |

| XSG-10 | 1000 | 6400 | 8400~14200 | 155~450 | 6×14 |

| XSG-12 | 1200 | 6700 | 12200~20400 | 225~675 | 8×16 |

| XSG-14 | 1400 | 7200 | 16700~27800 | 300~900 | 8×20 |

| XSG-16 | 1600 | 7700 | 21700~36200 | 400~1200 | 10×22 |

All dates are used for reference only. According to the condition of material.

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Türkiye

Türkiye ประเทศไทย

ประเทศไทย български

български русский

русский Svenska

Svenska Polski

Polski Română

Română Việt Nam

Việt Nam