YPG Series Pressure Granulating Spray Dryer

Product Name:YPG Series Pressure Granulating Spray Dryer

Details

Descriptions

1.This concentrator is a kind of device that can finish time dry and granulation at the same time. According to the requirement of technology, you can adjust charging pump pressure, flow, the size of the orifices, got the spherical particles you need of a certain proportion.

2.This concentrator work process: liquid materials is high-pressure input by charging pump, spray mistdroplet, then flow down with the hot air, most of the powder are collected from the bottom discharging mouth, waste gas and tiny power were separated by a whirlwind separator, the response rate is very high.

3.Materials of this comcentrator and the tower body contacted with material part, pipes, separator are SUS304, there are enough thermal insulation layer between internal tower body and the shell, filled material is super thin glass cotton, tower body includes glass door, watch mirror, light source and control meter which are all controlled and displayed by the electric control work station.

4.The heat source device of concentrator put to use steam heating or electric heater, that is easy to operate, start fast, compact structure, clean hot air, etc. In the electrical control cabinet equipped with electric heater to control adjusting device, make the inlet temperature to be adjusted steplessly. Lack electricity area can use steam heating or coal, oil hot air stove, that are partially or totally instead of electric heating device. Our factory can use different heating mode according to the actual needs of users.

Features

1.The drying speed is quick, be suitable for the thermal sensitive material. The product is ball particle, particle size is uniform , good liquidity and solubility, high purity and good quality.

2.Wide utilization, hot air drying and granulation, also can undertake cooling granulation, spray cry stallization, spray reaction, etc.

3.Simple and steady operation, convenient control, easy to realize automatic operation, product size, loose and thick degree, moisture can be adjusted in a certain range.

Applications

Chemical indudtry: Organic catalyst,resin,synthetic washing powder, oils, thiamin, intermediate of dyestuff, white carbon black,graphite, ammonium phosphate and so on.

Foodstuff: Amino acid and similar subatances, flavoring, protein, starch, dairy products, extractiv. from coffee, fish powder, extractive from meat and o on.

Pharmaceutical: Chinese traditional medicines, pesticide, antibiotic, medical drinkinng and so on.

Ceramics:Magnesium oxide, kaoline, All kind of metallic oxide, dolomite and so on.

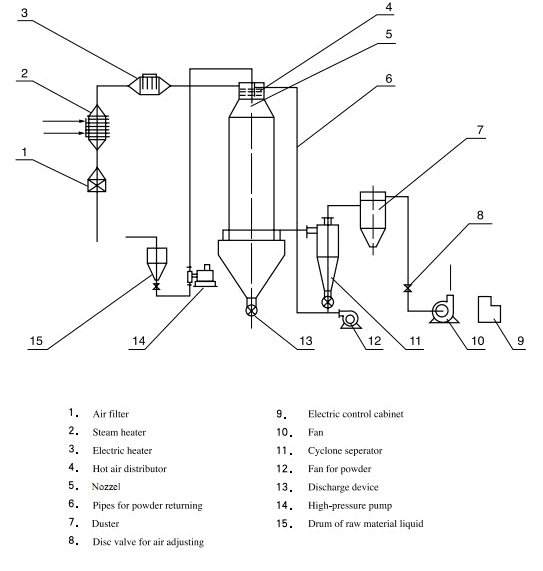

Flow chart Technical parameters

Technical parameters

| Model | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Water evaporation capacity(kg/h) | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Overall dimension (ØxH) (mm) | 1600x890 | 2000x11500 | 2400x13500 | 2800x14800 | 3200x15400 | 3800x18800 | 4600x22500 |

| High pressure pump pressure | 2-10 | ||||||

| Power (KW) | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| Inlet air temperature (°C) | 300 ~ 350 | ||||||

| Product water contents (%) | less than 5;and 0.5 can be reached | ||||||

| Material restoration (%) | > 97 | ||||||

| Electric heating (KW) | 75 | 120 | 180 | When the temperature is lower than 200°C, the parameters should be calculated according to the practical condition. | |||

| Electrically producing steam (MPa+KW) | 0.5+54 | 0.6+90 | 0.6+108 | ||||

All dates are used for reference only. According to the condition of material.

Note

1.evaporation and the characteristics of the materials, the above parameters for reference only, need according to the material properties of selection

2.The particle diameter materials they can adjust the process control

3.Supporting device including charging device, heating device, and the storm the distributor, bag dust extractions, spray precipitator, induced draft fan, etc.

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Türkiye

Türkiye ประเทศไทย

ประเทศไทย български

български русский

русский Svenska

Svenska Polski

Polski Română

Română Việt Nam

Việt Nam