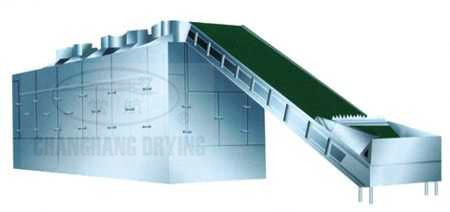

DCG Series Multi-layer Penetrating Mesh belt Dryer

Product Name:DCG Series Multi-layer Penetrating Mesh belt Dryer

Details

Descriptions

DCG series mult-layer penetrating mesh-belt dryer with my band in the traditional dry basis, to develop a new type of drying equipment. This device complies with the modern concept of environmental protection, machine design, compact,production capacity, product quality. Continuous production, high degree of automation is the ideal alternative to the traditional oven on low temperature for a long time to be a dry material is rare equipment.

Principles

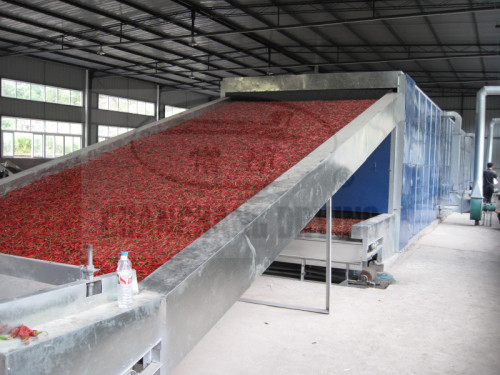

Dried by the lifting equipment from the device into the dryer on top of the top belt. Hot air from the bottom up layer by layer through the mesh, the material came from the top down in order with each network, the devices were in full heat and mass exchange; low temperature and humidity of the charge gas discharged by the device top, dry The material after discharge from the bottom side discharge belt.

Applications

Dehydrated vegetables: garlic, pumpkin, carrots, konjac, yam,bamboo shoots, peppers, onions, apples and so on.Chinese herbal medicines, feed and chemical raw materials industry, sheet, strip, block and granular materials dehydration.

Features

◎According to the characteristics of the material, the amount of air conditioning, heating temperature, residence time and material feed rate to obtain the best drying results.

◎The material several times with hot air heat and mass exchange, the exhaust air temperature is low, humidity is high, so the device has the characteristics of energy-efficient.

◎The unit is built-in heater, no secondary pollution; materials are not drying process with the outside world, they are able to fully comply with food hygiene requirements.

◎The material several times during the drying process of turning, and special hot air distribution equipment, making the color of dried material, dry uniform are better.

Technical parameters

| Item / Model | DCG-1.2×6 | DCG-1.2×8 | DCG-1.5×8 | DCG-1.5×10 | DCG-2×10 | DCG-2×12 | DCG-2×14 |

| Belt area | 36 | 48 | 60 | 75 | 100 | 120 | 140 |

| Steam pressure | 0.4~0.7 | ||||||

| Operation temperature | Inlet air temperature:60~150℃ Exhaust temperature30~55℃ | ||||||

| Drying Period | 30~120 | 45~180 | 45~180 | 60~240 | 60~240 | 75~300 | 90~360 |

| Steam consumption | 140~280 | 190~380 | 240~480 | 300~600 | 400~800 | 480~960 | 560~1120 |

| Steam Consumption | 210~420 | 280~560 | 360~720 | 450~900 | 600~1200 | 720~1440 | 840~1680 |

| Power | 13 | 18 | 24 | 35 | 39 | 36 | 54 |

| Weight(t) | 11 | 13 | 16 | 18 | 20 | 23 | 26 |

| Overall Dimensions(mm) | 9500×1500 ×3385 |

1150×1500 ×3385 |

1150×1800 ×3385 |

13500×1800 ×3385 |

13500×2300 ×3385 |

15500×2300 ×3385 |

17500×2300 ×3385 |

All dates are used for reference only. According to the condition of material.

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Türkiye

Türkiye ประเทศไทย

ประเทศไทย български

български русский

русский Svenska

Svenska Polski

Polski Română

Română Việt Nam

Việt Nam