PLG Series Continual Plate Dryer

Product Name:PLG Series Continual Plate Dryer

Details

Descriptions

PLG Series Continual Plate Dryer Descriptions Plate dryer is a kind of high effective conducting and continuous drying equipment. Its unique structure and operating principle determine that it has advantages of high heat efficiency, low energy consumption, small occupying area, simple configuration, easy operating and control as well as friendly operating environment etc. It can be widely used in drying process in the fields of chemical industry. Pharmaceuticals,agricultural chemicals, foodstuff, fodder, process of agricultural and sideline products etc, and is well received by various sectors in their practical usage. Now there are three big categories, named normal pressure, closed and vacuum styles; four sizes of 1200, 1500, 2200 and 3000; and three kinds of materials, namely A(carbon steel),B(stainless steel used for those all parts where materials are contacted) and C(on the basis of B to add stainless steel materials for vapor pipes, main shaft and support, and stainless steel linings for cylinder body and top cover). With a drying area being from 4 to 180 square metres, now we have hundreds of models of series products and various kinds of auxiliary devices available to meet requirements of drying materials for customers.

Applications

Drying, heat decomposition, combustion,cooling, reaction, and sublimation

1. Organic chemicals

2. Mineral chemicals

3. Pharmaceutical and foodstuff

4. Feed and fertilizer

Features

(1) Easy control, wide application

1. Regulate thickness of materials, rotating speed of main shaft, number of harrow’s arm, style of and sizes harrows achieve best drying process.

2. Each layer of drying plate can be fed with hot or cold media individually to heat or cold materials and make temperature control accurate and easy.

3. Dwell time of materials can be accurately adjusted.

4. Single flowing direction of materials without return flowing and mixing, uniform drying and stable quality, no re-mixing is required.

(2) Easy and simple operation

1. Start stop of dryer is quite simple

2. After material feeding is stopped, they can be easily discharged out of the dryer by harrows.

3. Careful cleaning and observation can be carried inside the equipment through large-scale viewing window.

(3) Low energy consumption

1. Thin layer of materials, low speed of main shaft, small power and energy required for conveying system of materials.

2. Dry by conducting heat so it has high heating efficiency and low energy consumption.

(4)Good operation environment, solvent can be recovered and powder discharge meet the requirements of exhaust.

1. Normal pressure type: as low speed of air flow inside the equipment and moisture being high in upper part and low in lower part,dust powder couldn’t float to the equipment, so there is almost no dust powder in tail gas discharged from the moist discharge port on the top.

2. Closed type: equipped with solvent recovery device that can recover organic solvent easily from moist-carrier gas. The solvent recovery device has simple structure and high recovery rate, and nitrogen can be used as moist-carrier gas in closed circulation for those subject to burning, explosion and oxidation, and poisonous materials in order for safe operation. Especially suitable for drying of flammable, explosive and poisonous materials.

3. Vacuum type: if the plate dryer is operating under vacuum state, it is particularly suitable for drying heat sensitive materials.

(5) Easy installation and small occupying area.

1. As the dryer is in a whole for delivery, it is quite easy to install and fix at site only by hoisting.

2. As drying plates being arranged by layers and installed vertically, it takes a small occupying area though drying area is large.

Principle

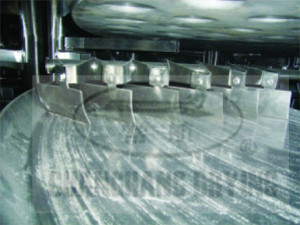

Wet material from the feeder is continuously applied to the top of the first layer of the drying plate dryer, with leaf rake rake arm for rotating movement, so that the rake arm continuously over copying material. Material along the spiral flow index drying plate surface, in small dry material on the disk is moved to the outer edge, in all material on the disk to move to and from middle chutes into a small drying plate. The size of the drying plates are arranged alternately, the material to be continuously through the whole dryer. Hollow drying plate through the heating medium, heating medium in the form of a saturated steam, hot water or heat conducting oil heating medium by dry plate, one end into, from the other end of export. The dried materials from the last layer of the drying plate to the bottom shell, and will be moved by rakes to the discharge port. Wet steam escaping from the material, is located in the exhaust outlet, a vacuum type dryer wet steam by the vacuum pump on the top cover mouth out. The dry material discharged from the bottom layer can be packed directly. By adding the finned heater, condenser for solvent recovery, bag type dust collector, dry mixing mechanism, blower fan and other auxiliary equipment, the drying capability can be raised, drying the paste and heat sensitive materials, can be easily recovered solvents, and can carry on the pyrolysis and reaction.

Technical parameters

|

All dates are used for reference only. According to the condition of material.

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Türkiye

Türkiye ประเทศไทย

ประเทศไทย български

български русский

русский Svenska

Svenska Polski

Polski Română

Română Việt Nam

Việt Nam