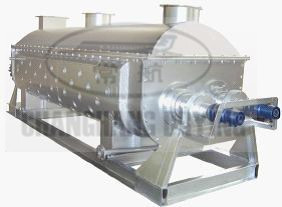

JYG Serier Oar Dryer

Product Name:JYG Serier Oar Dryer

Details

Descriptions

◎Oar drier is low speed churned drier that equipped oars inside equipment. The damp raw material is churned to ample conecting wigh hot carry and the surface, its structure can ehoruzontal, double scrolls of fore scrolls.

◎There are hot air style and transfer style two stlyles. The drying in hot air style is completed through conection of hot air and material. Intranster style, material is conected with hot surface to drying , ia can prevent pollution of material.The air outlet is few, effection is high, small size, save energy and prevent pollution of air.

◎It is suitable for drying in plastic, resin, inorganic compounds machine, fertilzer, feed, dyestuff,starch, mud and so on.

Features

◎Compact struture, small occupied space, high degree of heat conducting, best heat effeat. In general heat effect is attion to 80%-90%, it is a kind of device in saing energy.

◎Low speed, it is difficult to break into shaping of granule and slice raw material.

◎To raw material, wide use, easy to operate and raw material is adjustable from few minuters to few hours.

◎The attachment is simple, and will save invetment.

◎There is many uses by it, such as drying, cooling recoverying air, kesponding, heating and so on.

Mounting structure diagram

Technical parameters

|

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Türkiye

Türkiye ประเทศไทย

ประเทศไทย български

български русский

русский Svenska

Svenska Polski

Polski Română

Română Việt Nam

Việt Nam