HOME > PRODUCTS > Drying Machine

DY-1600 Pigment Dryer

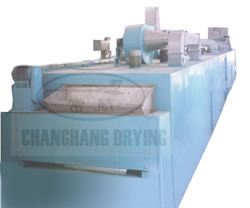

Product Name:DY-1600 Pigment Dryer

Keywords:Pigment Dryer

Overview:Pigment belt dryer factory is designed and developed products, professional for pigment industry a variety of material drying, a successful alternative to previously by oven drying technology

Details

Descriptions

Pigment belt dryer factory is designed and developed products, professional for pigment industry a variety of material drying, a successful alternative to previously by oven drying technology. This machine is suitable for a wide range, after drying the product quality index are higher, but also greatly save manpower. Material and energy for drying, and implement the automatic, continuous stepped pace, and is a novel energy-saving drier.

Pigment belt dryer factory is designed and developed products, professional for pigment industry a variety of material drying, a successful alternative to previously by oven drying technology. This machine is suitable for a wide range, after drying the product quality index are higher, but also greatly save manpower. Material and energy for drying, and implement the automatic, continuous stepped pace, and is a novel energy-saving drier.

Principles

Material in the spiral extruding mechanism into strips, even into the belt conveyer belt. Net belt with 16 ~ 20 the purpose of stainless steel net, composed of variable frequency adjustable rotating device to drive the belt in the dryer box to move at a constant speed, it is, two wind circulation on the material stream through. Air circulation through the blower, heater, the hot air distribution plate of material for heat exchange drying.

In the process, the moisture content of air larger gas through the wet exhaust port, regulating valve, exhaust fan exhaust. The other part of the gas from the circulating fan for circulating heating, in order to achieve the heat energy fully utilized, a small amount of leakage is part of material, by cleaning system to the screw discharging exhaust to ensure continuous operation, drier. Paint drying generally uses two section of belt dryer used in series, which is divided into a feeding section and a discharge section. The feeding section of the material with high water content, permeability is poor, so the use of paving thickness, speed teach fast, drying temperature is high. According to the nature of the material, the temperature is generally around 120, most of the water in the material feeding section off into the material, the moisture content of materials to teach less, air or material, and material water content is mainly the internal moisture requires a certain amount of drying time, the network should be put in the position with a walking slower, material layer thickening. According to the character of material, drying temperature can not exceed material of bearing temperature. Drying temperature in the case of a temperature measuring point through the electromagnetic valve to control the steam amount, so as to achieve the purpose of temperature control. Through the two dry, better play the belt dryer performance. After drying the material water uniformity, color strength, gloss, with other drying equipment drying product quality has bigger rise.

Material in the spiral extruding mechanism into strips, even into the belt conveyer belt. Net belt with 16 ~ 20 the purpose of stainless steel net, composed of variable frequency adjustable rotating device to drive the belt in the dryer box to move at a constant speed, it is, two wind circulation on the material stream through. Air circulation through the blower, heater, the hot air distribution plate of material for heat exchange drying.

In the process, the moisture content of air larger gas through the wet exhaust port, regulating valve, exhaust fan exhaust. The other part of the gas from the circulating fan for circulating heating, in order to achieve the heat energy fully utilized, a small amount of leakage is part of material, by cleaning system to the screw discharging exhaust to ensure continuous operation, drier. Paint drying generally uses two section of belt dryer used in series, which is divided into a feeding section and a discharge section. The feeding section of the material with high water content, permeability is poor, so the use of paving thickness, speed teach fast, drying temperature is high. According to the nature of the material, the temperature is generally around 120, most of the water in the material feeding section off into the material, the moisture content of materials to teach less, air or material, and material water content is mainly the internal moisture requires a certain amount of drying time, the network should be put in the position with a walking slower, material layer thickening. According to the character of material, drying temperature can not exceed material of bearing temperature. Drying temperature in the case of a temperature measuring point through the electromagnetic valve to control the steam amount, so as to achieve the purpose of temperature control. Through the two dry, better play the belt dryer performance. After drying the material water uniformity, color strength, gloss, with other drying equipment drying product quality has bigger rise.

Transportation and installation

1.Because the equipment volume, heavy weight, lifting the transport should grasp the focus, to prevent distortion.

2.The installation does not need to put foot, single use can be directly placed on the ground and correction levels. In the operation of the chain and the rotating part requirement card without interference phenomenon.

3.In the two series, before and after to join each other and maintain a level, material capable of automatically turning to flow to the second band network formed a series production line.

4.The installation of electrical equipment should be consistent with the requirements, to ensure safety.

5.Installation ended before commissioning, deal with the speed reducer, chain transmission bearing and other parts, add the lubricating oil

Matters needing attention

1.Before starting, check the fan power supply wiring is reliable, fan turning right or not.

2.Electric box should be reliable grounding.

3.The motor is in normal type operation.

4.Frequency control system function and control should be consistent with the requirements. Inverter should be strictly refer to manual operation, to prevent damage.

5.Network with the steering must be correct, rotating flexible, natural, no card network, beating phenomenon, with no reverse network.

6.Heater inlet, should first vapor duct on the drain valve is opened, drain pipe of condensed water, the bypass valve is opened, the line through vapor rust away impurities, and then close the valve, then let the trap begins to work, and should be checked for the heater, trap, electromagnetic valve works whether normally.

7.Please, less discharge screw rotation direction is normal

8.After the power is switched on, should check the electrical components, temperature control, frequency conversion system pulse dust collector are working correctly.

9.Check the extruding machine speed whether it meets the requirements, there are other sundries box. Especially the extruding machine after use if there are many residue material product in the machine, must rinse with water after driving, do not have any metal objects into the body material box so as to avoid rolling bad drum

10.All of the above all in compliance with the requirements of the formal feed operation

Boot

Open total power machine parts operation. Generally running 10 minutes after the start of feeding, when starting up, according to the following order of operations.

1.Open the steam inlet valve ( oven temperature measuring point electromagnetic valve control )

2.Open cycle fan (note that the motor is running normally after PV station opened)

3.Open exhaust fan (note that the motor is running normally after PV station opened)

4.Open the drying chamber belt conveyor controller buttons, turn to normal after ( when the temperature reached the requirements )

5.Open bar extruding machine, the speed from slow to fast ( according to the test material thickness setting speed )

6.Open bottom cleaning system ( discharging screw conveying mechanism )

7.Open ( pulse number and pulse controller setting should be cleaned regularly feed box material )

8.Open finished charging system (to ensure that the discharging flow)

Open total power machine parts operation. Generally running 10 minutes after the start of feeding, when starting up, according to the following order of operations.

1.Open the steam inlet valve ( oven temperature measuring point electromagnetic valve control )

2.Open cycle fan (note that the motor is running normally after PV station opened)

3.Open exhaust fan (note that the motor is running normally after PV station opened)

4.Open the drying chamber belt conveyor controller buttons, turn to normal after ( when the temperature reached the requirements )

5.Open bar extruding machine, the speed from slow to fast ( according to the test material thickness setting speed )

6.Open bottom cleaning system ( discharging screw conveying mechanism )

7.Open ( pulse number and pulse controller setting should be cleaned regularly feed box material )

8.Open finished charging system (to ensure that the discharging flow)

Shutdown

Shutdown according to the following order of operations:

1.Close the feeder, shutdown when feeding material to clean machine.

2.Close the steam valve, should be in the general feeding, discharging network with no material when off steam.

3.Closed circulating fan: by feeding section began to chase a shutdown.

4.Close the dehumidifying fan: by feeding section by starting station closed.

5.Closed belt drive variable frequency controller.

6.Closing valve bottom cleaning device.

7.For all materials to clean up after the closure, the total power.

Technical parameters

|

Feeding period | The material | ||||

| Bandwidth | 1.6 | 1.6 | ||||

| Length of dry section | 10 | 10 | ||||

| Vapor pressure | 0.4-0.6 | |||||

| Use temperature | 80-130 | |||||

| Material thickness | 50-80 | |||||

| Heat transfer area | 840 | 672 | ||||

| Drying time | 0.6-1.30 | 0.6-1.5 | ||||

| Circulating fan quantity | 5 | 5 | ||||

| Circulating fan power | 20 | 11 | ||||

| The dehumidification blower number | 2 | 1 | ||||

| The dehumidification blower power | 6 | 2.2 | ||||

| Net belt discharging power | 0.75 | 0.75 | ||||

| Clean the discharge power | 0.55 | 0.55 | ||||

| Outline dimensions | 22210×3000×3090 | 22210×3000×3090 | ||||

| Weight | 8000 | 7800 | ||||

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Türkiye

Türkiye ประเทศไทย

ประเทศไทย български

български русский

русский Svenska

Svenska Polski

Polski Română

Română Việt Nam

Việt Nam